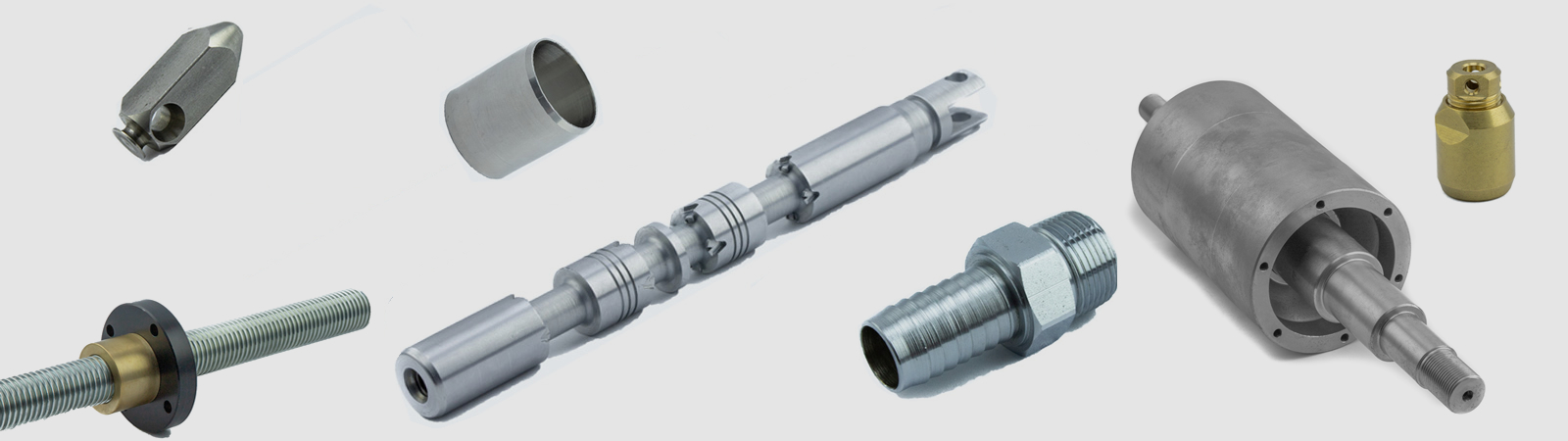

Machining is a manufacturing process in which power-driven machine tools such as saws, lathes, milling machines and drill presses are used with a sharp cutting tool to mechanically cut the material to achieve the desired geometry. The traditional machining processes include turning, boring, drilling, milling, broaching, sawing, shaping, grinding, planning, reaming and tapping. Types of machines that produce precision machine components include screw machines (both single spindle and multiple spindle bar machines), CNC controlled horizontal and vertical machining centers and CNC lathes. These machines utilize either metal bar stock, cast or forged metals. The quantity, accuracy, shape, finish and material will determine what type of machine should be used.

Manufacturing Capabilities

- CNC Turning Centers with Bar Feeder

- Horizontal Machining Centers

- Vertical Machining Centers

- CNC Lathes

- Robotic Machining Cells

- Multi Spindle Screw Machining

- Special Turning Centers

- Swiss CNC & CAM Equipment

- Thread Rolling

Secondary Services

- Grinding, Centerless Grinding, Threading, Broaching, Flattening, Crimping, Bending, Welding, Heat Treating, Painting, Plating, Anodizing

Materials

- Castings: Grey Iron, Ductile Iron, Steel, Stainless Steel, Brass, Bronze, Aluminum

- Bar Stock: Aluminum, Steel, Stainless Steel, Copper, Brass, Bronze, Tubing, Plastic

Commercial

Commercial