February 17th, 2020

FREE CUSTOM PROTOTYPE SPRINGS

We pride ourselves in efficiently producing precision springs and wire forms, and for a limited time we are offering them to you FREE!

We will evaluate your custom design prior to producing your parts and if it fits our current capabilities, we will produce your prototype parts using our exacting standards, at no expense to you.

Posted in Springs & Wire Forms | No Comments »

August 16th, 2019

PLAN TO ATTEND

MAKE CONNECTIONS…

VALUABLE REASONS

FOR ATTENDING

LEARN New Technologies & Processes

MEET Quality Suppliers & Reps in Person

DISCOVER Proven Solutions for your Problems

SOLVE Workforce/Employee Shortages

PURCHASE at Special Show Prices

HIGHLIGHT EVENTS:

• Wisconsin Business & Industry Luncheon presented

by the Wisconsin Manufacturers & Commerce

(WMC) Foundation

• “Connection Reception” Networking Event

sponsored by First Citizens Bank with Student

Competitors attending with resumes

• Next Generation Manufacturing Summit

presented by BizTimes Milwaukee

• Student and Team Competitions in the Welding

Pavillion and Automation & Robotics Lab

• “Industry 4.0: Four IoT Technology Trends That Will

Impact Small to Midsized Manufacturers” [Tuesday’s

Keynote Address on the BMO Harris Bank Main Stage]

• Eleven enlightening FREE seminars held in “The Hub”

sponsored by the Wisconsin Economic Development

Corporation [WEDC]

…TO TECHNOLOGY

Posted in Uncategorized | No Comments »

July 2nd, 2019

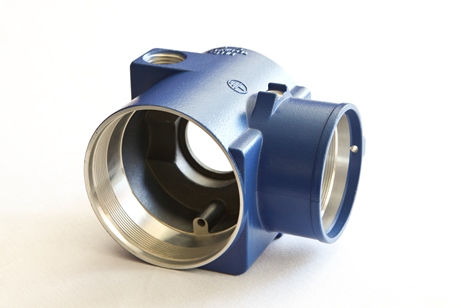

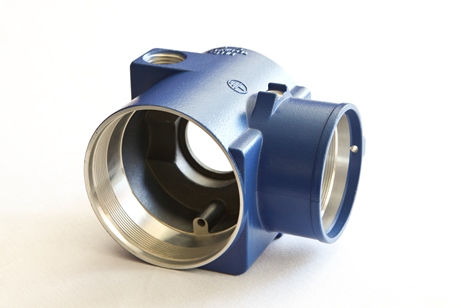

| Are you looking for help to Procure AND Machine your Castings? |

| Many businesses have recognized a gap between procuring the casting from the foundry and machining it to the engineered drawing. Gorham Inc. has a supply chain that works with grey iron, stainless steel, bronze and aluminum foundries and will then machine the casting to your desired specifications. |

| Would you like to Outsource your Precision Machining? |

| With the labor pool shrinking, many businesses are looking to outsource their internal machining capabilities. Whether it is screw machining, CNC machining, Swiss screw machining or even thread rolling, we have seen a trend to outsource. Precision machining has been a core competency of Gorham Inc. for over 50 years. |

Tags: CNC MACHINE, MACHINE CASTINGS, OUTSOURCE PRECISION MACHINING, precision machining, PROCURE CASTINGS, Screw Machine, SWISS SCREW MACHINE, Thread Rolling

Posted in Castings, Machine Shop, Precision Machining | No Comments »

June 7th, 2018

Problem solving is at our core. We are able to take on some of the toughest metal fabrication challenges anywhere. Our cross-functional, engineered-solutions team has gathered an incredible amount of knowledge working closely with product engineers. We offer rapid and cost-effective product development and fabrication, and then manufacture and deliver the final product.

Tags: CNC Turret Punching, Custom Fabricating, Engineering Design, Fastener Installation, illinois, Laser Cutting, Machining, Powder Coat Painting, Press Brake Forming, Prototype Design, Rolling and Forming, Sawing, Sheet Metal Fabrication, tube bending, Tube Fabrication, Welding, wisconsin

Posted in Metal Fabrication, Tube Bending | No Comments »

April 3rd, 2018

There are potentially SIGNIFICANT cost savings by converting a machined component to powder metal. Making quality components from powdered metal produces cost savings by reducing, or even eliminating, expensive machining and material scrap. Our Materials Engineer will help you choose the right powder metal mix to give your component the properties it needs, while ensuring the lowest possible cost.

Give us a call today to see if we can unlock some savings for you.

Tags: Gear Actuators, Gear Drives, Gear Motors, Gear Reduction, Helical Gears, illinois, Knob Locks, Lever Locks, Mortise Locks, Motion Control Applications, Padlocks, Panic Bars, Powder Metal Components, Pump Gears, wisconsin

Posted in Powder Metal Parts | No Comments »

October 12th, 2017

From prototype to production, we have your metal stampings covered. We have partnered with industry leading manufacturers that have a proven track record of saving our customers money with their diverse manufacturing equipment, while providing product development and engineering support. Our goal is to help engineer a custom part or solution that is more efficient and better quality than anything that existed before.

From prototype to production, we have your metal stampings covered. We have partnered with industry leading manufacturers that have a proven track record of saving our customers money with their diverse manufacturing equipment, while providing product development and engineering support. Our goal is to help engineer a custom part or solution that is more efficient and better quality than anything that existed before.

Tags: 600 ton press, assembly, cost savings, Custom Engineered, illinois, Laser Cutting, Machining, Metal stampings, Multi-Slides, robotic welding, Welding, wisconsin

Posted in Metal Stampings | No Comments »

August 15th, 2017

If you are looking for a machined casting, then look no further. Our team will manage your project from sourcing the raw casting to machining your part to print. Our casting supply base is large and proven. Our equipment diversity guarantees that your product is produced with the most cost effective manufacturing process. Whether you are looking for a CNC, Swiss, or screw machine part, our portfolio of manufacturers has you covered. Please contact us for a quote or for more information.

If you are looking for a machined casting, then look no further. Our team will manage your project from sourcing the raw casting to machining your part to print. Our casting supply base is large and proven. Our equipment diversity guarantees that your product is produced with the most cost effective manufacturing process. Whether you are looking for a CNC, Swiss, or screw machine part, our portfolio of manufacturers has you covered. Please contact us for a quote or for more information.

Tags: aluminum, anodizing, Bending, brass, Broaching, bronze, CAM, CNC Lathes, Copper, Die Casting, Ductile Iron Casting, fabricating, Flattening, Grey Iron Casting, Grinding, Heat Treating, illinois, Investment Casting, Machined Casting, Material Sourcing, mechanical assembly, Packaging, Painting, Parts Washing, plastic, Plating, precision machining, Sand Casting, screw machining, Stainless, Steel, Swiss, Thread Rolling, Threading, Tubing, Turning Centers, Welding, wisconsin

Posted in Castings, Precision Machining | No Comments »

June 14th, 2017

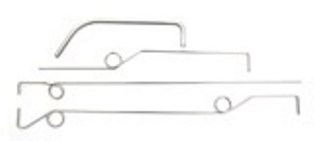

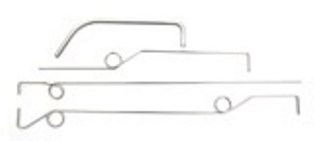

If you are looking for a Wisconsin based spring and wire form manufacturer, look no further. The Gorham team has partnered with Spiros Industries. We are pleased to offer prototyping, engineering support, samples and solutions for your spring and wire form requirements.

Compression Springs, Extension Springs, Torsion Springs

Custom Wire Forms, from D-Rings and S-Hooks to Unique Wire-Bending Shapes

Tags: assembly, Compression Springs, custom, D-Rings, Design, engineering, Extension Springs, Fabrication, prototypes, S-Hooks, Springs, Torsion Springs, Wire Bending, Wire Forms

Posted in Springs & Wire Forms, Uncategorized | No Comments »

May 4th, 2017

Offering a one-stop solution for value-added aluminum extrusions. Focused inventory plans resulting in greater cost controls. Quality improvement ideas due to extensive product and process knowledge. Lead time reduction utilizing our lean manufacturing principles.

Offering a one-stop solution for value-added aluminum extrusions. Focused inventory plans resulting in greater cost controls. Quality improvement ideas due to extensive product and process knowledge. Lead time reduction utilizing our lean manufacturing principles.

Your single source for:

- Aluminum Extruding

- Fabrication

- Machining

- Tooling

- Anodizing

- Assembly

- Packaging

Fabrication Capabilities:

- Cutting

- CNC Machining

- Punching & Drilling

- Deburring / Mechanical Finishing

- Bending

Aluminum’s natural metallic and reflective appearance can add an aesthetically pleasing look to your assembly. Combine this with the seamless nature of extrusions, the complexity of the design, the corrosion-resistant nature of aluminum, and its ability to accept a wide range of finishes ~ aluminum extrusions offer advantages unmatched by other materials and processes.

Tags: aluminum, anodizing, deburring, Design, extruding, Extrusions, Fabrication, illinois, Machining, metallic, tooling, wisconsin

Posted in Aluminum Extrusions | No Comments »

March 17th, 2017

Why Powder Metal?

Significant Cost Savings, Complex and Unique Shapes, Minimal to No Waste in Production, Low to High Volume Runs, High Material Strength, Part to Part Consistency, Cost Efficient, Lower Tooling Cost, No Tool Maintenance, Dimensional Control, Elimination of Costly Cutting , Varied Surface Finishes, Tight Tolerances

Materials Used:

High Strength Steel, Stainless Steel, Bronze, Brass, Soft Magnetics

Tags: brass, bronze, complex shapes, consistency, cost efficient, cost savings, dimensional control, high strength, illinois, low tooling cost, magnetics, metal parts, minimal waste, Powder Metal, Steel, surface finishes, Tight Tolerances, wisconsin

Posted in Powder Metal Parts | No Comments »

From prototype to production, we have your metal stampings covered. We have partnered with industry leading manufacturers that have a proven track record of saving our customers money with their diverse manufacturing equipment, while providing product development and engineering support. Our goal is to help engineer a custom part or solution that is more efficient and better quality than anything that existed before.

From prototype to production, we have your metal stampings covered. We have partnered with industry leading manufacturers that have a proven track record of saving our customers money with their diverse manufacturing equipment, while providing product development and engineering support. Our goal is to help engineer a custom part or solution that is more efficient and better quality than anything that existed before. If you are looking for a machined casting, then look no further. Our team will manage your project from sourcing the raw casting to machining your part to print. Our casting supply base is large and proven. Our equipment diversity guarantees that your product is produced with the most cost effective manufacturing process. Whether you are looking for a CNC, Swiss, or screw machine part, our portfolio of manufacturers has you covered. Please contact us for a quote or for more information.

If you are looking for a machined casting, then look no further. Our team will manage your project from sourcing the raw casting to machining your part to print. Our casting supply base is large and proven. Our equipment diversity guarantees that your product is produced with the most cost effective manufacturing process. Whether you are looking for a CNC, Swiss, or screw machine part, our portfolio of manufacturers has you covered. Please contact us for a quote or for more information.

Offering a one-stop solution for value-added aluminum extrusions. Focused inventory plans resulting in greater cost controls. Quality improvement ideas due to extensive product and process knowledge. Lead time reduction utilizing our lean manufacturing principles.

Offering a one-stop solution for value-added aluminum extrusions. Focused inventory plans resulting in greater cost controls. Quality improvement ideas due to extensive product and process knowledge. Lead time reduction utilizing our lean manufacturing principles.

Commercial

Commercial